illinois clean fuels.

better fuels for a better future.

about illinois clean fuels.

Illinois Clean Fuels is developing recycling and synthetic fuel plants that convert municipal garbage into jet fuel, paired with carbon capture and storage. This better-than-net-zero process provides a cost-effective route to help decarbonize some of the most difficult-to-decarbonize sectors of the world economy.

our solutions.

creating a better-than-net-zero integrated solution.

municipal waste management

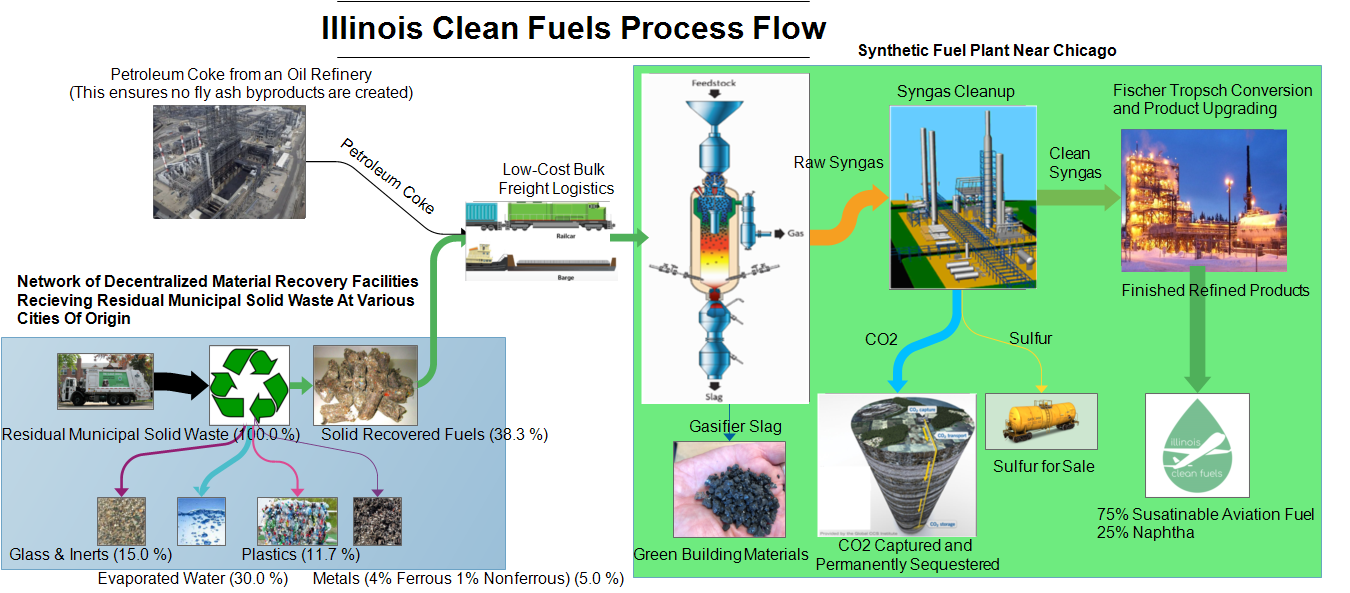

The recycling plants on the front end of our supply chain process residual municipal solid waste that otherwise would have been landfilled or incinerated, providing next-generation municipal solid waste management solutions for the communities we serve. These plants recover valuable raw materials and low-carbon energy that can be used at either a synthetic fuel plant or a cement plant.

sustainable aviation fuel

Our synthetic fuel plant will convert that energy to ultra-clean jet fuel in a process paired with carbon capture and storage. The Sustainable Aviation Fuel this plant produces will have a lifecycle climate impact very far below zero. When combined, this system represents the cleanest and most climate-friendly possible option for the treatment of municipal waste.

the facts & figures

what our technology can do.

per year of municipal solid waste is generated in the United States

%

is recycled...source-separated (blue bin) recycling cannot process contaminated & commingled materials in black bag garbage

%

resource recovery...the recycling plants in our feedstock supply chain are specifically designed to manage "black bag" residual waste, recovering raw materials & energy that are currently wasted

how it works

We are project developers, not technology inventors. ICF will deploy the best available process technologies from around the world, as they are proven out at a commercial scale. While the plants we deploy will expand the scope of what has already been demonstrated, all of the core technologies required to eliminate the climate impact of municipal waste treatment, aviation, and cement production already exist and have already been demonstrated at scale. Our job is to deploy them.

We have built a team of the most senior industry leaders, engineers, process technology innovators, and operations specialists to make this a reality.

address

790 Estate Drive

Suite 200

Deerfield, IL 60015