municipal solid waste solutions

municipal solid waste solutions in the U.S. & Canada

With dwindling landfill capacity, incinerators rusting out, rapidly escalating disposal costs, and increasingly stringent climate regulation, North America urgently needs a new generation of climate and environment-friendly residual municipal solid waste management infrastructure.

ICF’s advanced Material Recovery Facilities (MRFs) will replace landfills and incinerators, recovering recyclable raw materials and useful low-carbon energy.

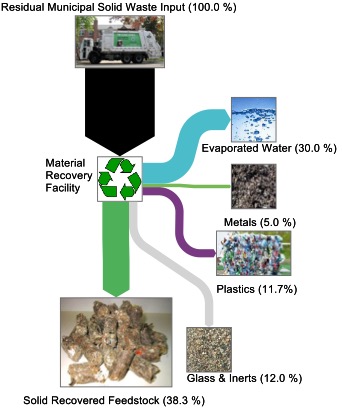

A Material Recovery Facilities job is to take an inconsistent mix of literally everything (garbage), recover as many valuable recyclable raw materials as possible, and convert the remainder into a consistent and high-quality low-carbon energy feedstock that can be safely and reliably used for the production of higher value products, like jet fuel or cement. These are high-tech facilities that provide local jobs, eliminate odors, and reduce traffic impacts to the communities they serve.

our solution

While we do employ a few of the same technologies in portions of our process, the MRFs we are developing are very different from plants designed to handle “blue bin” source-separated recyclables. Our MRFs are specifically designed to manage commingled and contaminated “black bag” residual MSW that would otherwise be landfilled or incinerated. This is a compliment to, not a substitute for, traditional “blue bin” recycling, and is designed to manage the volumes that the source-separated blue bin system cannot utilize.

Doing this requires a lot of processing and sorting, using advanced technology such as drying, optical sorting, machine vision, and AI.

how it works

The Municipal Solid Waste is shredded down to a consistent size, and then magnets and eddy currents are used to separate the metals.

Density separation uses gravity, air jets, and vibration to separate heavy and light materials, and separate inerts such as rocks, dirt, sand, and glass. Optical sorters use high-tech cameras, AI, and air jets to separate, identify, and sort specific types of plastics (both for recycling and to eliminate potentially damaging elements such as chlorine from the fuel stream).

The energy fraction is either baled or pelletized to be shipped by rail or barge to a synthetic fuel plant or cement plant, where it will deliver further significant climate benefits.

Each material recovery facility

- Enables cities to achieve “zero waste” and net zero climate goals

- Creates 31 jobs

- Eliminates odors from the handling of municipal waste

- Creates a reliable outlet for waste even when transport systems are disrupted

- Eliminates emissions and community impacts caused by landfilling and incineration

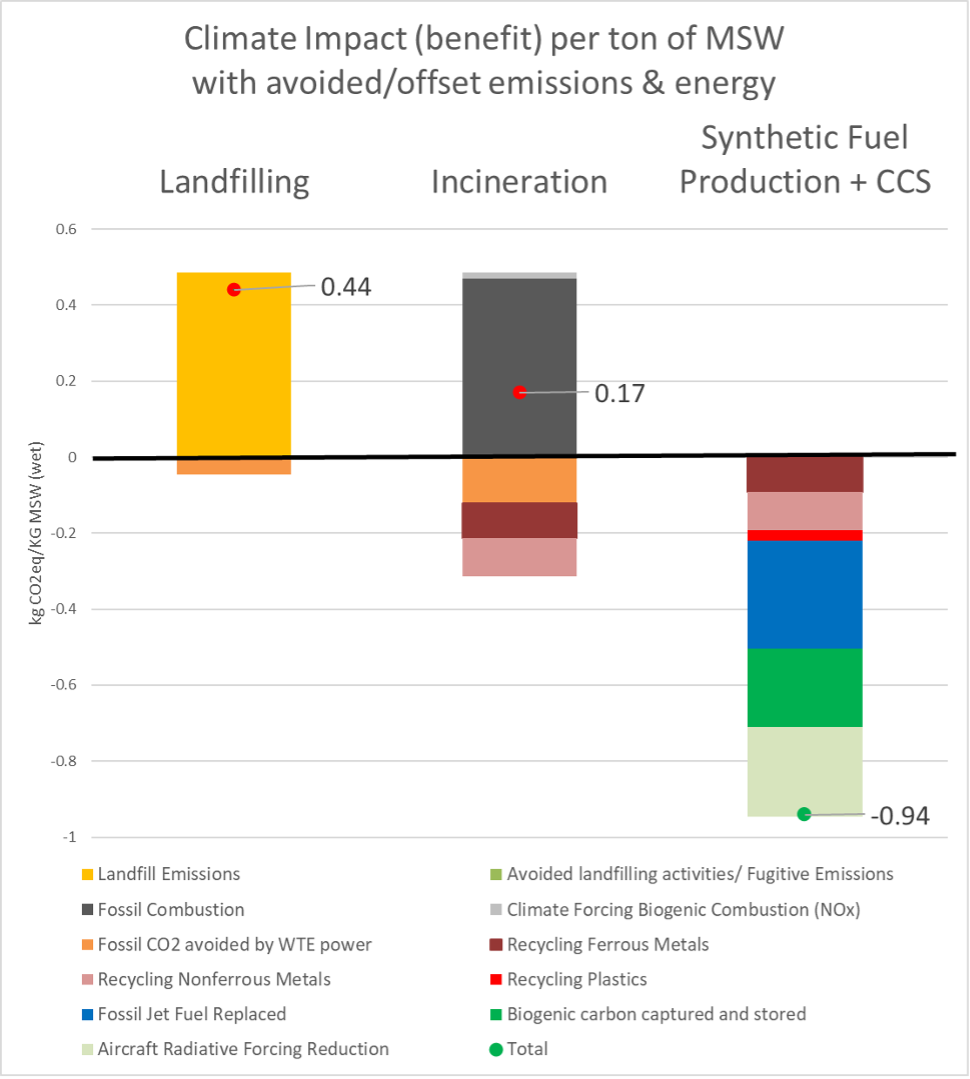

The climate benefits: Getting to better-than-net-zero. We prepared this graph to attempt to present an “apples to apples” comparison of the climate impacts and benefits of treating 1 ton of municipal solid waste using various methods.

The next generation of synthetic fuel plants (including the one we are developing) and cement plants will integrate carbon capture and storage into their process. When the energy from municipal waste is used in a Carbon Capture and Storage integrated process, the treatment of municipal solid waste goes from being a climate emissions source to becoming a significant source of net atmospheric carbon removal.

Municipal waste contains a lot of biomass (effectively, carbon sourced from the air). In a landfill, that biomass breaks down into methane (whose climate impact is 25-80X worse than CO2) and becomes a major emissions source. When the biomass in waste is used correctly in the right industrial process, it can instead become a key source of carbon reduction or removal by displacing the need for fossil fuels, and serving as a way to cost-effectively source CO2 from the atmosphere to eliminate the climate impact of fuels and cement production.

the environmental benefits:

- Recycling existing raw materials consumes far less energy than producing new materials.

- One particularly stark example is the production of aluminum. Using recycled aluminum saves 95% of the energy required to make the same aluminum from a virgin source.

In most typical locations in the US, the energy savings from just the aluminum that we recover from each MRF is 4X greater than all of the electricity required to run the entire material recovery facility. Not counting the benefits and producing energy from the other metals, plastics, and the energy fraction of waste.

Our team is made up of veteran leaders, innovators, and operators in the North American municipal waste industry. We are building a pipeline of projects, and are capitalizing with a goal to implement dozens of these recycling plants distributed throughout the US and Canada.

address

790 Estate Drive

Suite 200

Deerfield, IL 60015