sustainable aviation fuel

sustainable aviation fuel solutions

Aviation is widely regarded as one of the most difficult-to-decarbonize sectors of the world economy. Commercial aircraft have few options to decarbonize other than switching to another drop-in replacement sustainable aviation fuel.

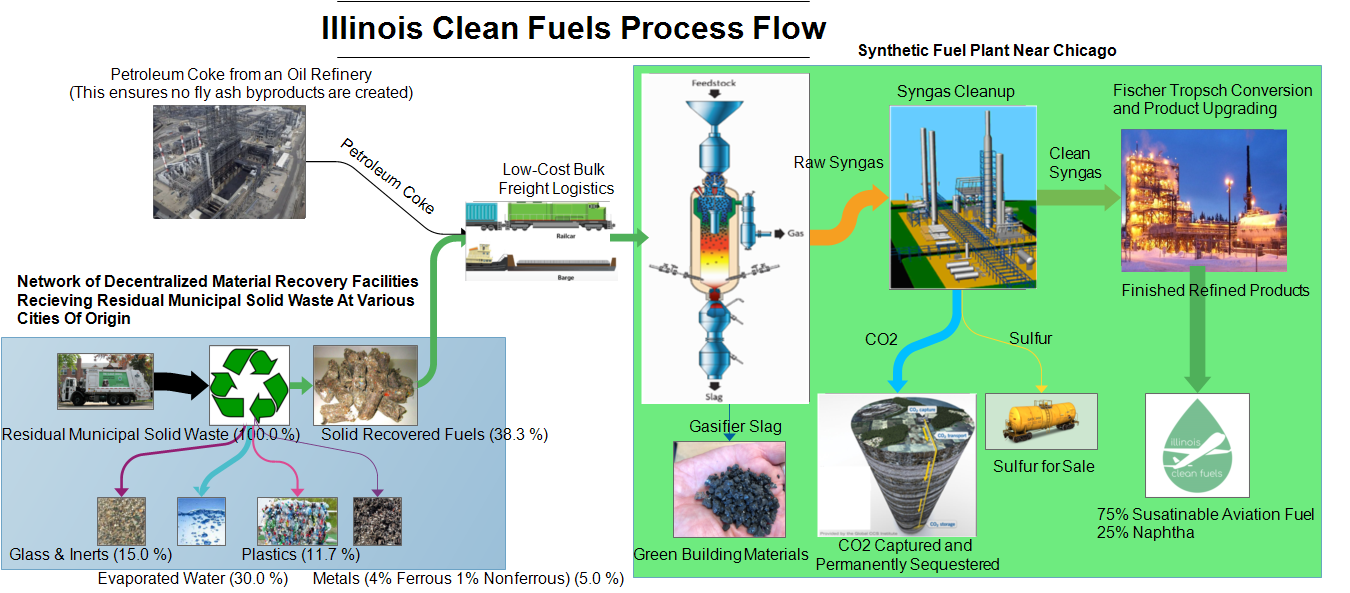

ICF’s synthetic fuel plant will be located in Illinois, near Chicago.

ICF will produce large quantities of Sustainable Aviation Fuel (“SAF”) that will be sold at price parity with conventional jet fuel. ICF’s process is NOT a technology innovation. It is the aggregation and integration of a century-old process with modern engineering developments that allow for the use of biomass and municipal waste as feedstock. Our feedstock supply chain will consist of a decentralized network of many advanced Material Recovery Facilities (“MRFs”) designed to process raw Municipal Solid Waste (“MSW”) and recover energy and recyclable raw materials and energy. ICF is developing a portfolio of such projects in parallel with our synthetic fuel plant.

our process flow.

our technology

Our economic value add comes from the integration of four key technologies that work synergistically to minimize production cost and maximize environmental performance:

Density separation uses gravity, air jets, and vibration to separate heavy and light materials, and separate inerts such as rocks, dirt, sand, and glass. Optical sorters use high-tech cameras, AI, and air jets to separate, identify, and sort specific types of plastics (both for recycling and to eliminate potentially damaging elements such as chlorine from the fuel stream).

- Using waste as a feedstock reduces feedstock cost vs farmed biomass or fossil feedstocks. Cost-effectively sourcing biogenic carbon that would otherwise be a liability if landfilled.

- Efficient rail and/or barge supply chains aggregate the feedstock stream and affordably transport it for processing.

- Properly scaled, our synfuel plant design maximizes process efficiencies and reduces conversion costs.

- Carbon Capture & Sequestration (“CCS”) radically reduce the lifecycle carbon intensity of the fuel, which in combination with biogenic input carbon delivers a better-than-net-zero climate impact. It eliminates the climate impact of fuel production and uses AND facilitates the removal of excess CO2 from the atmosphere.

Every source of Sustainable Aviation Fuel that is currently on the market costs more to produce than conventional fuels. Working together, sustainable fuels production and municipal waste management can eliminate cost barriers and implement new advanced technologies, delivering unprecedented environmental and climate benefits in a way that is economically superior to landfilling, incineration, and conventional jet fuel production.

how sustainable aviation fuel works

1.

ICF’s synthetic fuel plants use a process called gasification to break down the SRF energy from MSW into hydrogen and carbon “syngas.” Gasification as a process pre-dates electricity, and is used worldwide for a wide array of energy and chemicals processes ranging from fuels, to fertilizer to electricity production.

2.

The syngas is refined down to the parts-per-billion level, capturing all sulfur, heavy metals, and excess CO2. Excess CO2 is captured and stored in permanent geologic sequestration.

The pure hydrogen and carbon syngas is then reacted over a catalyst that builds it back up into a jet fuel molecule in a process called Fischer Tropsch conversion.

3.

FT conversion has been used extensively for fuel production around the globe for almost a century. Over 740,000 barrels per day of fuel are already produced using this process at over 11 plants around the world. The synthetic fuel that Fischer Tropsch produces is higher quality than petroleum-derived fuel. It contains virtually no sulfur or aromatics, meaning that it burns much more cleanly and completely than conventional fuels, emitting fewer particulates, and reducing the formation of climate-forcing contrails.

4.

Carbon Capture and Sequestration (“CCS”) is the process by which excess CO2 from the process is captured and transported deep underground where it is permanently and safely stored in geological formations.

ICF will have among the lowest capture cost of any industrial process because CO2 capture is part of the fundamental chemistry of SAF production. We are able to capture huge quantities of CO2 with almost no additional cost.

Working with other major industry partners, we plan to use our scale to add enough CO2 transport and storage infrastructure that we will also enable other neighboring industries (such as cement plants, chemical plants, power plants, and refineries) to CCS integrate. This will help facilitate broad, low-cost regional decarbonization of heavy industry all around our project site. We will store our CO2 in Mt. Simon Sandstone. This formation is among the best geology in the world for safe and permanent storage of functionally unlimited quantities of CO2.

address

790 Estate Drive

Suite 200

Deerfield, IL 60015